CCO PLATES

HB OM100

Weld Overlay Wear Plates

Overview:

HB OM100 combines a chromium carbide composite cladding with a mild steel base through fusion bonding. Its structure features a dense, uniform distribution of chromium carbides within the cladding layer, creating a bimetallic material that delivers exceptional abrasion resistance while retaining ductility for welding and forming. Engineered for extreme wear and moderate-impact conditions

HB OM100 performs very well under severe abrasion and low to moderate impact environments.

Product Details

Specification:

| Standard plate size | 1400*3000MM | 1500*3000MM | 1400*3500MM | 2000*3000MM | ||||

| Coating thickness | 3-50mm | |||||||

| Base material thickness | 3-100mm | |||||||

Other sizes and thickness available on request. | ||||||||

Typical properties:

Weld overlay composition:

| Element | Content |

| Carbon | 3-5% |

| Silicon | 0.5‒2.5% |

| Manganese | 0.5‒2.5% |

| Chromium | 20-28% |

| Others | Bal |

Note: The content of Cr and C varies in different plate thickness.

Bulk Hardness: HRC 57-63

Abrasion Test result: <= 0.19g( testing under ASTM G65, procedure A)

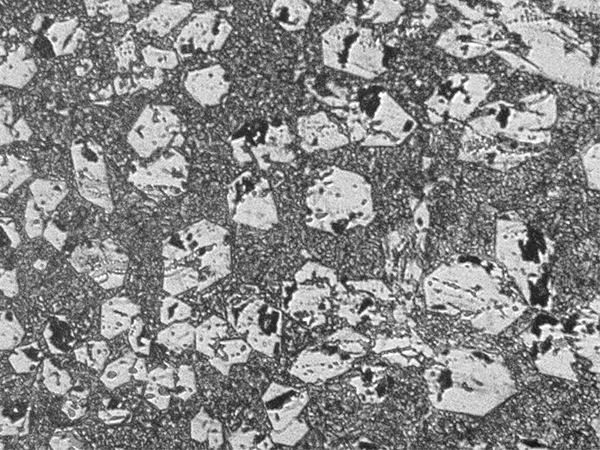

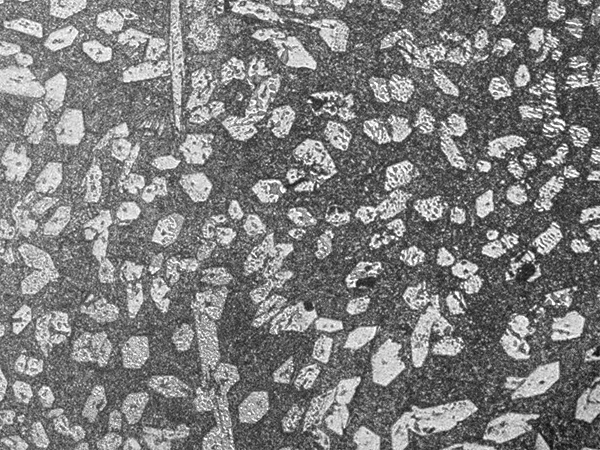

Surface Finish: X200 metallographic Structure:

Fabrication:

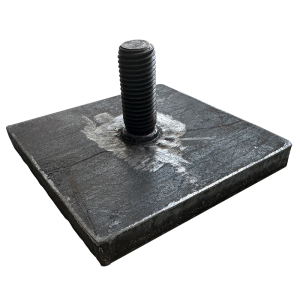

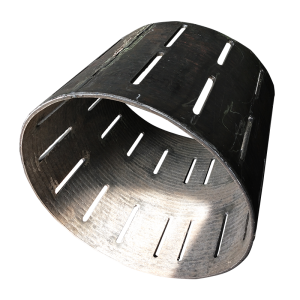

We have the capabilities to fabricate ready-to-go wear liners by cutting,punching,bolting,bending,welding,assembling,grinding or otherwise working on the product.

Applications:

| Business | Application |

| Mining | Feed chute liners, Bin liner, Cyclones, hoppers, conveyor systems, Truck bed & bucket liners, dozer blades |

| Cement | Screen plates, mill liner, stragage bins, piping systems, separator fans, chutes, classifier cones, outlet ducts… |

| Steel | Fan blade &housings, coke vibrating screen plates, pelletizing plants, sinter screens, coke screens, feed bins, distribution chutes, blast furnace armor plates. |

| Power generation | Coal transfer systems, screens, classifiers, silos, bunkers, fans, chutes |

If you need further information, please feel free to let us know. | |