CCO PLATES

HB OM200

Weld Overlay Wear Plates

Overview:

HB SM200 utilizes submerged arc welding technology to fuse chromium carbide composite cladding onto a mild steel base. The cladding features a high density of chromium carbides uniformly distributed across its thickness, forming a bimetallic structure that delivers exceptional abrasion resistance while retaining ductility for forming and welding applications.

HB SM200 performs very well under severe abrasion and low to moderate impact environments.

Product Details

Specification:

| Standard plate size | 1400*3000MM | 1500*3000MM | 1400*3500MM | 2000*3000MM | ||||

| Coating thickness | 4-40mm | |||||||

| Base material thickness | 4-100mm | |||||||

Other sizes and thickness available on request. | ||||||||

Typical properties:

Weld overlay composition:

| Element | Content |

| Carbon | 3.5-6.5% |

| Silicon | 0.5‒2.5% |

| Manganese | 0.5‒2.5% |

Chromium | 25-40% |

Others | Bal |

Note: The content of Cr and C varies in different plate thickness.

Bulk Hardness: HRC 57-63

Abrasion Test result: <= 0.26g( testing under ASTM G65, procedure A)

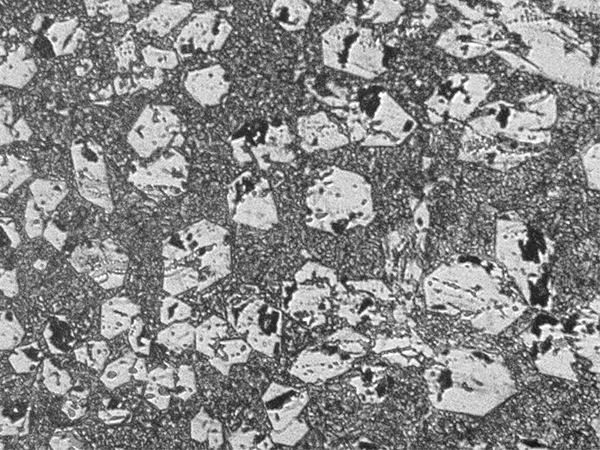

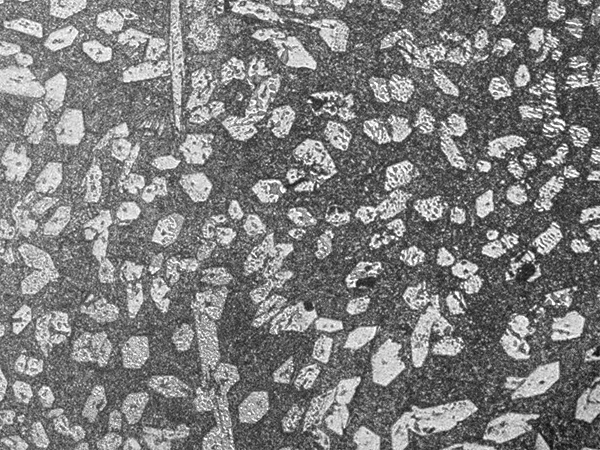

Surface Finish: X200 metallographic Structure:

Fabrication:

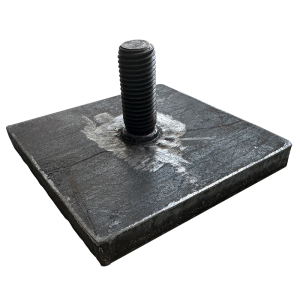

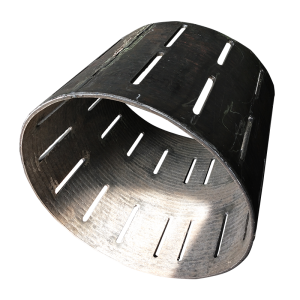

We have the capabilities to fabricate ready-to-go wear liners by cutting,punching,bolting,bending,welding,assembling,grinding or otherwise working on the product.

Applications:

| Business | Application |

| Mining | Feed chute liners, Bin liner, Cyclones, hoppers, conveyor systems, Truck bed & bucket liners, dozer blades |

| Cement | Screen plates, mill liner, stragage bins, piping systems, separator fans, chutes, classifier cones, outlet ducts… |

| Steel | Fan blade &housings, coke vibrating screen plates, pelletizing plants, sinter screens, coke screens, feed bins, distribution chutes, blast furnace armor plates. |

| Power generation | Coal transfer systems, screens, classifiers, silos, bunkers, fans, chutes |

If you need further information, please feel free to let us know. | |